Advanced Manufacturing

Collaborating through design, prototyping, and manufacturing

Our team of experts collaborates throughout the design, prototyping, and manufacturing process to create manufactural designs, decreasing costs and saving time. Our collocated facilities provide us with agility to rapidly tackle tough technical challenges from concept analysis and development through testing and production—in one location.

Solutions complex

The Solutions Complex provides laboratory, assembly, fabrication, exploitation, integration, and collaboration space to facilitate rapid and affordable technology development for both commercial and government customers. The 226,500 ft2 facility contains areas that range from unclassified conference and collaboration areas to Top Secret and Sensitive Compartmented Information (SCI)-cleared areas.

We offer mission-focused engineering services, including modeling and simulation, design and analysis, software development, reverse engineering, advanced systems integration, and test. Our experts provide specialized system and subsystem development for the following:

- Radars and sensors

- Intelligence and electronic warfare

- Missiles and strike systems

- Unmanned systems

- Cyber and IT solutions

- Space systems

- Critical infrastructure protection

- Avionics

Technical solutions

Our in-house machining center offers the equipment and expertise for precision machining and fabrication. The robust combination of highly skilled personnel, state-of-the-art machinery, and high-end software provides the ability to rapidly develop hardware for research and development (R&D) prototyping and limited production.

- Manufacturing and quality engineering

- Supplier quality and technical management

- CNC machining and metal fabrication

- Prototyping

- Aerospace welding

- Mil-spec painting

- Composites: Mold and part fabrication

- Mechanical assembly and integration

- Inspection and nondestructive testing

- Classified workspace

The machining center utilizes ISO-compliant management information systems to track, in real time, all aspects of a project from planning through material ordering, production, in-process inspection, final inspection, packaging, and shipping. Additionally, it is fully capable of operations in a Department of Defense (DoD) classified environment.

- We signed an agreement with Pro-Beam to acquire the largest electron beam welding system

- The 22 feet long, 22 feet wide and 22 feet high system is capable of supporting government and commercial programs, both unclassified and classified

- The company has also completed acceptance of a smaller system from Pro-Beam, a 20 feet long, 7 feet wide and 7 feet sister system

- Both systems will be installed in Huntsville during 2020

The Dr. Stephen M. Gilbert advanced manufacturing facility

The Dr. Stephen M. Gilbert Advanced Manufacturing Facility provides an advanced automation manufacturing and assembly production capability. With sophisticated software, the facility provides increased production volume, enables rapid changeover, increases reliability, and houses a detailed inventory system. It also offers classified manufacturing.

Major production and assembly programs:

- Automotive manufacturing

- Cable production

- Electronics manufacturing for printed circuit boards

- Final product assembly for large and small systems

- GroundAware® surveillance system

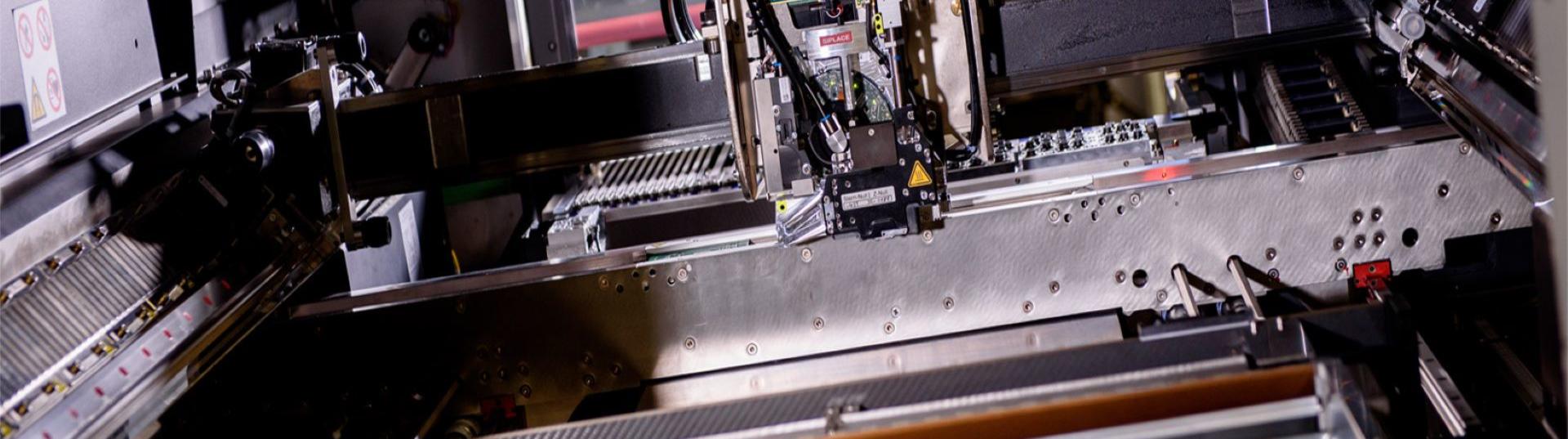

Surface Mount Technology

The Surface Mount Technology (SMT) equipment selected focuses on scalability and flexibility. We will be able to introduce new products quickly, change setups quickly, handle the most challenging board and component technologies, and produce any batch size with high utilization and efficiency, to meet the demands of the high mix of products required by our customers.

- Automated parts storage, and sophisticated software to group similar products together, which reduces change-over times between jobs.

- Advancements in off-line programming and verification, so programs are ready far in advance of actual production.

- A wider range of component sizes that can be auto-placed, so fewer hand-placed parts.

- Automated component-level traceability, for more detailed lot tracking.

- Automated verification of solder joint integrity, which results in higher reliability and reduced rework of boards.

Nanotechnology

Nanotechnology is the control of matter on the atomic and molecular scale. While still in its infancy, nanotechnology aims to drive the next major technological revolutions in space flight, computing, medicine, aeronautics, energy systems, and manufacturing. Some specific applications include molecular-scale electronics, optical computing, ultra-strong materials, hybrid biological-artificial systems, and self-replicating nanoelectromechanical systems.

We are developing methods of manufacturing nano-scale materials, where it is possible to control not only the resulting material properties (e.g., strength, conductivity, etc.), but also to control the shape, composition, and placement of materials on the large scale. In this way, it is possible (for the first time) to perform additive manufacturing of entire complex systems, rather than just manufacturing individual components. For example, entire automobile engines could be printed from computer drawings, and they would function just as well as or better than a traditionally machined and assembled engine. And at that same time, the printed engines would cost less.

Today, manufacturing begins with raw materials, casts or forms them to create components, then machines and assembles them to create systems. The traditional approach results in high labor costs and wastes valuable materials. A unique capability within the US, nano-additive manufacturing is typically limited to national research laboratories and universities. We invested in a 226,000-square-foot Solutions Complex to bring greater capabilities in research and development to this area. The new facility has a dedicated laboratory to do this specialized applied research.

Additive manufacturing permits delivery of component geometries and materials to:

- Provide integrated materials and manufacturing solutions for a wide range of customers

- Carry out scalable synthesis from the nano-scale to large-scale systems

- Synthesize custom nanomaterials for specific applications

- Develop novel three-dimensional micro-electro-mechanical systems (MEMS) and hybrid 3-D microelectronics

- Create braided cables and weaved textiles of functional materials (including damage-resistant textiles that limit degradation/fraying of a weave)

- Develop ultra-lightweight material lattices for high strength-to-weight ratio aerospace and military components

- Develop custom near-net-shape composite materials of metal-matrix composites (MMCs) or ceramic-matrix composites (CMCs)

- Create high-strength, high-temperature, and/or tough components for demanding applications

- Perform laser and ion-beam processing, as well as lithography and surface micromachining methods