Leidos installs innovative air system to Orion for Artemis III flight

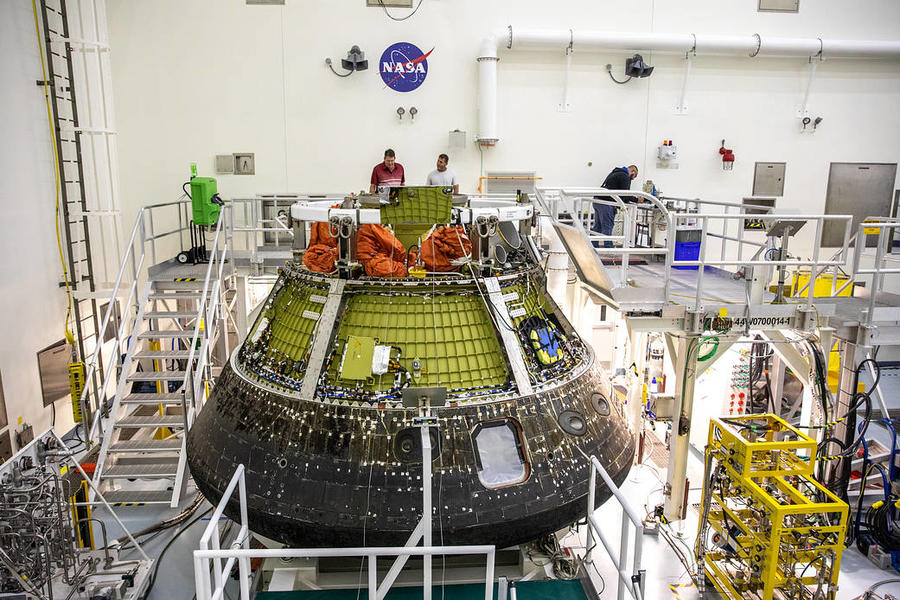

Technicians secure the Orion capsule on a platform inside the Multi-Payload Processing Facility (MPPF) at Kennedy Space Center in Florida. Photo: NASA

The laser air monitoring system is a small but critical component for crewed missions.

“Houston, we have a problem.”

Those infamous words were uttered during the aborted Apollo 13 mission back in 1970. Well, actually, Tom Hanks said them in the 1995 movie, but astronaut Jack Swigert said something pretty close when he called into NASA Mission Control to let them know an explosion had caused the crew’s oxygen tank to fail two days into the mission.

That mission, made famous by several movies and documentaries, is known as a successful failure for NASA because they managed to safely return all astronauts aboard the damaged spacecraft. Helping to ensure the event is not repeated is where the Leidos laser air monitoring system comes in.

The Laser Air Monitoring System (LAMS) provides critical protection to the crew in two ways. First, the sensitive pressure sensor will alert the crew aboard NASA’s Orion spacecraft during the Artemis missions of leaks in the system – before they could potentially cause any harm to the crew. Second, it determines how much oxygen, carbon dioxide and water vapor are in the cabin and spacesuit air systems. The technology integrates with Orion to maintain safe air quality and atmosphere for the astronauts.

“What the LAMS team has accomplished is truly incredible. We built on NASA’s idea and turned around to deliver human-rated spaceflight hardware in just over two years, having never built an instrument like this, much less for a human-rated application for NASA,” LAMS Chief Engineer Jason Pohly said. “This is a testament to the talent, ingenuity and dedication of everyone on the team.”

The group began working on the system back in 2018 when it was using tunable diode laser absorption spectroscopy (TDLAS) technology to develop a LAMS for measuring cabin and space suit pressure, as well as oxygen, carbon dioxide and water vapor in the Orion spacecraft. At that time, NASA had only recently unveiled its massive Artemis program and all its plans for returning people to the moon. However, the agency wasn’t looking for things to move slowly – they wanted things done safely and effectively, but quickly. Leidos was more than happy to step up to the challenge and meet NASA’s requirements.

Led by Pohly, the company’s technical experts took into account NASA stringent system requirements and the necessary objectives needed to create a Criticality 1 human spaceflight system as they began their work towards what seemed like an impossibly tight timeline – research, prototyping, procurement and assembly, integration, testing and delivery all by July 2020. Oh, and they would need four completed units, not just one. But the team persevered, getting the flight stack (two sensors for cabin loop and two sensors for the astronauts’ suit loop) to NASA’s Johnson Space Center in Houston, Texas, for acceptance testing.

“The LAMS team has been through a rollercoaster over the past few years,” said Heather Woods, deputy program manager for LAMS at Leidos. “From design challenges and timeline crunches, the team continued to work together to push through any challenges thrown their way.”

Those units were shipped from Houston to the agency’s Kennedy Space Flight Center in Florida and tested for use in Orion for Artemis II, which will be the first crewed mission to the moon since Apollo 17 launched in 1972. That flight is currently scheduled for no earlier than November 2024, and the four astronauts for this mission were announced at Johnson Spaceflight Center in April – three men and a woman who will make history.

Given the short development timeline and the new technology being employed on Artemis II, the LAMs team had additional challenges to address to meet all requirements and certify the LAMs for future Artemis missions. NASA initiated a follow-on contract in 2021 to produce more LAMS for Artemis III, and the NASA team collaborated with Leidos on ways to improve the design to achieve the full accuracies needed for long-term exploration. NASA and the LAMS team took in lessons learned from the first go-round and implemented design changes, process improvements as well as software updates necessary to get the second set of units designed. The engineers found themselves working weekends and multiple shifts in order to finalize builds and complete calibration testing. In the end, the final product was made more efficiently, and the software reached the highest standard NASA sets for this type of technology, Class A, meaning every single line of code must be independently tested and verified, which includes bidirectional requirement tracing.

Leidos officially delivered Artemis III’s LAMS system in November 2022. In February 2023, it became one of the first pieces of environmental controls equipment installed in Orion for that mission.

“When the delivery to NASA occurred, the Leidos LAMS team breathed a collective sigh of relief,” Program Manager Trista Niemann said. “It was a long road with a mostly co-located team of electrical, optical, mechanical, software, quality and test engineers along with the production control and assembly, integration and test teams. Experts from multiple divisions came together, and keeping everyone motivated wasn’t hard since we had a shared vision in mind.”

While the team enjoys a brief moment of reprieve, they know there is still work to be done. After all, Artemis IV and V are coming up. But no one working on LAMS is too concerned. What’s two more to a group that’s already been through so much?

Artemis III is targeted for lift off in 2025. Artemis IV is a little farther out, waiting for its turn on the launchpad in 2028. It will also be the first time Orion and a human landing system dock at the brand new Lunar Gateway.

*Certain statements in this announcement constitute “forward-looking statements” within the meaning of the rules and regulations of the U.S. Securities and Exchange Commission (SEC). These statements are based on management’s current beliefs and expectations and are subject to significant risks and uncertainties. These statements are not guarantees of future results or occurrences. A number of factors could cause our actual results, performance, achievements, or industry results to be different from the results, performance, or achievements expressed or implied by such forward-looking statements. These factors include, but are not limited to, the “Risk Factors” set forth in Leidos’ Annual Report on Form 10-K for the fiscal year ended December 31, 2021, and other such filings that Leidos makes with the SEC from time to time. Readers are cautioned not to place undue reliance on such forward-looking statements, which speak only as of the date hereof. Leidos does not undertake to update forward-looking statements to reflect the impact of circumstances or events that arise after the date the forward-looking statements were made.